Manufacturers across automotive, electronics, medical, and industrial sectors increasingly need parts that combine durability, precision, and multi-material functionality. Traditional assembly methods—such as screws, adhesives, and manual fastening—are often slow, expensive, and prone to failure. This is where custom insert molding services offer a powerful solution.

Insert molding integrates metal and plastic into one solid component using advanced injection molding processes. It enhances strength, improves reliability, reduces assembly steps, and lowers overall production cost. Whether you are designing electrical connectors, threaded inserts, surgical tool components, or structural brackets, insert molding can significantly improve performance and longevity.

This detailed guide explains what insert molding is, how it works, the advantages it offers, common applications, and what to look for in a reliable custom insert molding supplier.

What is Insert Molding?

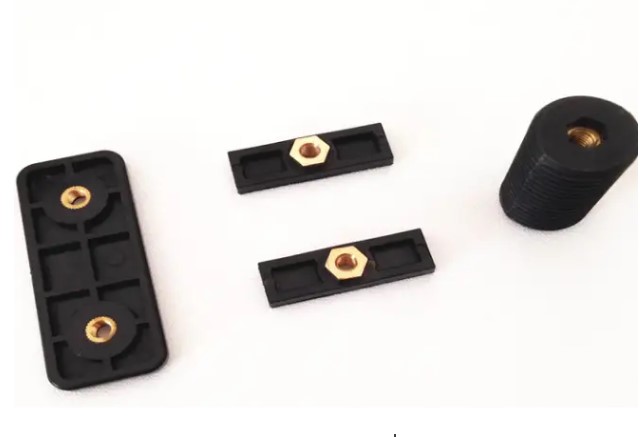

Insert molding is a specialized injection process where a pre-formed component—usually metal, threaded inserts, terminals, sensors, bushings, or fasteners—is placed into a mold. Molten plastic is then injected around it, creating a single integrated part.

Common insert materials include:

- Stainless steel

- Brass

- Copper

- Aluminum

- Pre-molded plastic parts

- Electronic components and contacts

The plastic resin bonds to the insert, forming a strong mechanical or chemical connection. Compared with traditional assembly, insert molding eliminates secondary fastening operations and offers far better part integrity.

How a Custom Insert Molding Service Works

A professional insert molding process typically includes:

1. Component Preparation

Metal inserts may be cleaned, degreased, plated, or heat-treated to improve bonding and corrosion resistance.

2. Manual or Robotic Insert Loading

Inserts are loaded into the mold either by hand (ideal for small batches) or by automated robotics (best for large volumes and high repeatability).

3. Injection Molding

Molten thermoplastic—such as PA66, PP, ABS, PC, PBT, or reinforced resins—is injected around the insert. Pressure forces the plastic to fill every contour and lock the insert in place.

4. Cooling and Ejection

Once cooled, the mold opens and the finished multi-material component is ejected.

5. Post-Processing

Depending on the application, parts may undergo trimming, ultrasonic welding, testing, or assembly.

This streamlined process results in stronger, more precise parts with fewer failure points.

Advantages of Custom Insert Molding Services

1. Stronger and More Reliable Components

Insert molding creates a powerful bond between metal and plastic. The plastic encapsulates the insert completely, preventing loosening, corrosion, and vibration-related failures.

2. Lower Production and Assembly Cost

By integrating inserts directly into the molded component, businesses can eliminate:

- Manual assembly

- Threading operations

- Gluing and fastening

- Multi-piece production

This greatly reduces labor and speeds up production.

3. Lightweight yet high strength

Insert molding allows manufacturers to replace heavy all-metal parts with lighter hybrid components that maintain high structural integrity.

4. Consistent Quality and Precision

Because inserts are accurately positioned inside the mold, the final product achieves excellent repeatability with tight tolerances.

5. Improved Product Durability

Insert molded parts resist:

- Pull-out forces

- Temperature cycles

- Chemical contact

- Mechanical stress

This results in longer product life and lower warranty issues.

6. Design Flexibility

Engineers can combine materials for:

- Electrical insulation

- EMI protection

- Waterproofing

- Mechanical reinforcement

- Heat resistance

This flexibility opens the door to innovative product designs.

Materials Commonly Used in Insert Molding

Choosing the right plastic and insert combination is crucial to performance.

Inserts

- Stainless steel

- Brass

- Copper

- Threaded inserts

- Bearings

- Bushings

- Pins and rivets

- Electrical terminals

- Sensors and electronics

Thermoplastic Resins

- ABS

- Nylon (PA6 / PA66 / PA+GF)

- PP

- PC

- PBT

- PEI, PPS, PEEK for engineering-grade components

The selection depends on temperature resistance, mechanical load, environmental exposure, and required bonding performance.

Industries That Depend on Custom Insert Molding Services

Insert molding serves as a backbone manufacturing process for many sectors.

Automotive Industry

Used for:

- Sensor housings

- Switch components

- Engine bay connectors

- Threaded mounts

- Metal-reinforced brackets

Insert molding provides vibration resistance and long-term stability.

Medical and Healthcare

Applications include:

- Surgical tool handles

- Stainless-steel–plastic assemblies

- Diagnostic device components

- Drug delivery mechanisms

Medical-grade materials ensure biocompatibility and smooth operation.

Electronics and Electrical

Insert molding is essential for:

- Cable connectors

- PCB housings

- Switch assemblies

- Coil frames

- High-voltage insulators

This ensures excellent electrical insulation and heat resistance.

Consumer Products

Commonly used for:

- Power tool parts

- Cosmetic devices

- Home appliances

- Kitchen utensils

The result is stronger, safer, and longer-lasting products.

Industrial and Mechanical

Used for gears, bearings, mounts, threaded inserts, and functional parts exposed to heavy loads.

How to Choose a Reliable Custom Insert Molding Supplier

A dependable supplier ensures stable production, strong bonding, and consistent quality. Here’s what to look for:

1. Strong Engineering and DFM Support

A professional team should be able to analyze:

- Insert geometry

- Plastic flow behavior

- Orientation requirements

- Stress points

- Shrinkage and warpage risks

Good design prevents defects before production begins.

2. Automation Capabilities

For large-volume production, look for:

- Robotic insert loading

- Vision inspection

- Multi-cavity tooling

- Automated demoulding

Automation improves cycle times and repeatability.

3. Advanced Tooling Capabilities

Insert molds require high precision. Choose suppliers with:

- CNC machining

- EDM and wire cutting

- Multi-stage tools

- Tight tolerance control

Tool quality directly affects part consistency.

4. Comprehensive Quality Control

Your supplier should follow standards such as:

- ISO 9001

- IATF 16949 (automotive)

- ISO 13485 (medical)

QC should include pull-out tests, insert alignment checks, and dimensional inspection.

5. Material Knowledge

A reliable manufacturer understands:

- Plastic–metal bonding behavior

- Thermal expansion differences

- Surface treatment for inserts

- Reinforced materials for added strength

Correct material pairing ensures long-term durability.

6. Flexible Production Options

Your supplier should handle:

- Prototyping

- Small pilot runs

- Medium and high-volume mass production

This allows your project to scale easily.

Why Insert Molding Improves Your Product Line

By choosing custom insert molding, you gain:

- Stronger and lighter parts

- Lower assembly cost

- Better product reliability

- Faster production cycles

- Enhanced safety and performance

- More appealing product designs

Manufacturers can achieve long-lasting, high-precision components ideal for demanding applications.

Final Thoughts: The Value of Custom Insert Molding Service

Custom insert molding services provide an efficient, precise, and cost-effective way to integrate metal and plastic into high-performance components. The process reduces assembly steps, improves durability, enhances mechanical strength, and allows designers to innovate with multi-material solutions.

Whether you’re developing automotive connectors, medical housings, industrial components, or electronic assemblies, a skilled insert molding manufacturer ensures stable bonding, tight tolerances, and superior product quality.